Project Overview

This empirical study compares the mechanical performance of titanium machined from mill stock material vs. additive manufactured titanium. The study also shows mechanical characteristics of machined titanium compared to direct laser sintering (DMLS) titanium that has undergone a shot peening process.

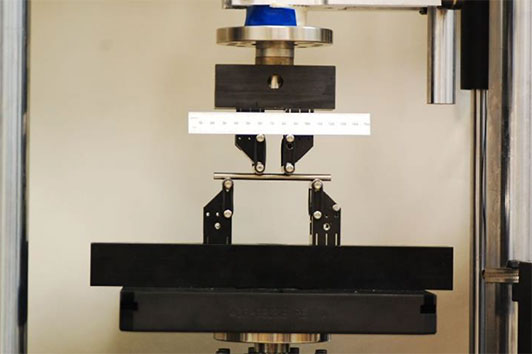

The scope is limited to evaluating Ø6mm round Ti6Al4V rods (per ASTM F136) in static and dynamic four-point bending per ASTM F2193. In addition, a static tensile testing (per ASTM E8) was performed to evaluate machined Ti6Al4V vs additive manufactured Ti6Al4V.

In the first comparison (machined vs additive manufacturing) there was no substantial performance difference in static testing, with a bending stiffness of 867.18 +/-28.53 (N/mm) for all specimens. For dynamic testing, the machined rods reached 2,000,000 cycles without evidence of failure at a stress of 167ksi. Applied stress was reduced to 69ksi for the DMLS rods to reach 2,000,000 cycles. Fracture occurred at 41ksi on the EB rods.

Testing to compare machined titanium vs shoot peened DMLS titanium is currently underway. The null hypothesis is that there is no difference between the mechanical performance and material characteristics between the different manufacturing and post-manufacturing processes